Tag Archive: Food Processing

-

JEC from A to Z: Level Indication – Devices to Improve Process Control and Inventory Management

If you don’t have someone on staff using the careful application of a hickory nut-loaded slingshot and his finely tuned sense of hearing to check the level of

your silos and bins (TRUE STORY), maybe you should consider our BinMaster® Bin Level Indicators for your inventory management and process control. Let us help you select the best solution for your application – we want to save you time, money, and support a much safer working environment for you and your employees!

your silos and bins (TRUE STORY), maybe you should consider our BinMaster® Bin Level Indicators for your inventory management and process control. Let us help you select the best solution for your application – we want to save you time, money, and support a much safer working environment for you and your employees!Bin Level Indicators Enhance Safety

- reduces the risk of accidents – no need for climbing ladders or onto bin roofs to routinely check bin levels

- explosion-proof certifications are available on many devices for volatile or dusty materials

Bin Level Indicators are User Friendly and Save Time

- easy to install and operate – highly skilled technical or operational staff not required

- eliminates frequent climbing and allows multiple bins to be monitored from a central location – manage from one up to 120 bins

- “fail-safe” feature offered on many devices that gives an immediate warning and instantaneous response in the event of a failure

- require virtually no maintenance – by design, the “de-energized” operation of the motor in BinMaster® rotaries places less stress on the motor and prolongs motor life

Bin level Indicators Improve Inventory Management and Optimize Storage Capacity

- automatically monitor materials and control processes avoiding costly spills, material waste, empty conditions, clogged chutes, jammed conveyors and unnecessary downtime – overfilling bins ruins materials, wastes time, makes a mess, and costs money

- improves inventory level accuracy and delivers more timely information regarding bin status allowing for just-in-time replenishment reducing the risk of shutting down operations if material should run out – advanced systems like the SmartBob from BinMaster® allow users to view multiple bins at a glance

Bin Level Indicators are Highly Cost Effective

- provide a solution for a wide variety of applications and every budget quickly paying for themselves in labor savings alone

- optimized storage capacity and replenishment cycles makes even the most advanced BinMaster® system a fast return on the investment

- designed to use less equipment to monitor more bins, can be configured to tie into existing control systems, and feature low power consumption and operating costs

Let us be your Complete Solution – we offer:

- Continuous Level Indication via BinMaster® SmartBob, 3DLevelScanner, RL Acoustic Level Scanner, Guided Wave Radar, Smartwave Pulse Radar Level Transmitter, and Ultrasonic Level Transmitter

- Point Level Indication via BinMaster® Capacitance Probes, Diaphragm Switch Level Indicator, Rotary Level Indicator, Vibrating Rod

- Tilt Level Indicators and Flow and Dust Detection also available

- Level indication equipment suitable for Pellets, Granulars, Powders and Most Other Bulk Solids – serving a variety of industries and applications including Grain, Seed & Feed; Chemical Processing; Aggregates & Cement; Food Processing; Bioenergy; Pulp & Paper; Petrochemicals; Plastics Manufacturing; Power Plants; Mining Operations; water/wastewater and more!

- View the Level Indication Product Selection Chart to find out which level indicator best fits your application.

-

JEC from A to Z: Electric Motors, Motor Controls and Gear Reducers

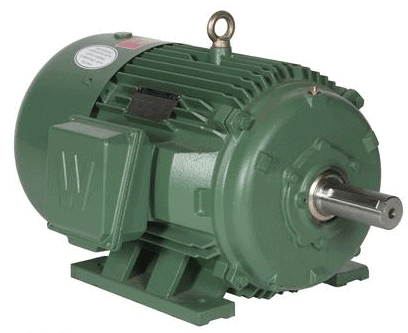

Electric motors are used by a wide variety of our dry bulk materials handling and materials processing customers like aggregates, asphalt, and concrete, chemical processing, food processing, foundry and metal fabrication, glass, paint, plastics and rubber manufacturers, textile mills, grain, feed, fertilizer, seed, lime, mining, power, pulp & paper, railroad, and recyclers just to name a few.

Electric motors are used by a wide variety of our dry bulk materials handling and materials processing customers like aggregates, asphalt, and concrete, chemical processing, food processing, foundry and metal fabrication, glass, paint, plastics and rubber manufacturers, textile mills, grain, feed, fertilizer, seed, lime, mining, power, pulp & paper, railroad, and recyclers just to name a few.To meet the needs of our diverse customer base, we offer a wide variety of general purpose premium efficiency electric motors and IEEE-841 electric motors with TEFC (Totally Enclosed Fan Cooled) enclosures, severe duty large frame electric motors, and premium efficiency explosion proof electric motors with TEXP (Totally Enclosed Explosion Proof) enclosures. We also offer shaft mount gear reducers and worm gear reducers, motor mounts, motor controls, temperature sensors, and other components, accessories, and options for your operation’s unique needs and environment.

If you operate blowers, bucket elevators, centrifugal pumps, compressors, conveyors, dust collectors, farm equipment, feeders, food processing equipment, hoppers, material handling equipment, packaging machinery, recycling equipment, screeners, screw conveyors, separation equipment, shakers, vibrating screens, etc., then great quality electric motors with all the necessary certifications keep your operation running optimally!

-

JEC from A to Z: Ducting

JEC from A to Z: Ducting…one of my most favorite product lines! I guess the clamp together and snap together products remind me of being a kid playing with tinker toys and erector sets only these products aren’t toys by any stretch of the imagination. They are heavy duty and they are HUGE! And because we serve so many industries, we make it our business to supply a wide variety of ductwork and accessories. If you handle the collection and removal of dust, fumes, mist, etc., you need ducting!

Maybe you handle agricultural dust, carbon dust, cement, chemicals, food and grain, fly ash, milk powder, flour, diaper fluff, paint products, paper, petrochemicals, plastic, spices, sugar, salt, textile dust, wood dust, pharmaceuticals, metal dust, metal shavings and have to deal with not only dust but with chemical fumes, fume exhaust, condensation, oil mists, smoke, vehicle exhaust, welding fumes, etc. Some of the industries represented by our customers who regularly purchase ductwork and related products from us are aggregates, agriculture, automotive, boatbuilding, chemical, concrete, food processing, furniture, lime, metalworking, mining, paint, paper, plastics, powder, recycling, textiles, woodworking, and the processing of other dry bulk materials.

We offer ductwork that is easy and fast to install, easy to clean out, has leak-tight laser welded seams, and is reusable – cutting installation and downtime! Some of our products clamp together without the need for welds, bolts, screws, flanges, special tools, precise measurements, or specialized skills and can also be taken apart easily for cleaning or reconfiguring due to floorplan changes. Some products are available in aluminum, stainless steel, or galvanized. Also available are leak-free systems, abrasion resistant linings, custom manifolds, duct packages, flex ducting, and a full complement of accessories making Jamieson Equipment Company the Complete Solution for your ducting needs!

Click here to view all ducting products on our website.

-

JEC A to Z: Conveyors & Conveyor Products

If you move dry bulk materials for agriculture, food processing, the mining of coal, rocks, limestone, gypsum, and precious metals, the processing of rocks into aggregates including gravel and sand, the processing of pharmaceuticals and other chemicals, producing concrete, asphalt, brick, and mortar, processing lumber or waste, manufacturing glass, plastics, or textiles, and so on, we have the conveyors, conveyor components, and accessories for you!

We offer Tubular Frame Truss Conveyors, Channel Frame Conveyors, Aerial Conveyors, Conveyors with variable lengths, Track Mounted Stackers, Transfer Conveyors, Groundline Conveyors, Radial Stackers, Telescoping Radial Stackers, Portable Conveyors, Stackable Conveyors, and Tunnel Reclaim Conveyors. And to keep your conveyors running smoothly and safely, we offer a full complement of component parts and accessories including Conveyor Belt Scales, Liner Material, Conveyor Belt Cleaners, Conveyor Belt Hoods and Covers, Conveyor Belting, Conveyor Controls, Conveyor Feed Systems, Conveyor Safety Controls, Motors, Gear Reducers, Conveyor Belt and Return Roll Guards, Hoppers and Feeders, Idlers and Return Rolls, Impact Beds, Industrial Ladders & Safety Gates, Material Flow and Speed Switches, Pulleys and Conveyor Take-ups, Temperature Sensors, Auto Greaser, Bearings, Clamp Down Rails, and Holdbacks. Click here to see our full line of conveyors and conveyor products.

-

JEC from A to Z: Bearings

Check out our full line of Bearings: Spherical and Tapered Roller Bearings, Mounted Bearing Units, Pillow Blocks, Corrosion Protection Bearing Units, Air Movement Bearing Units, Free Spinning Bearings, High Temperature Bearings designed to operate in temperatures up to 450 °F, Sealed Bearings, Heavy Duty Pillow Blocks, and Takeups. When compiling a list of all the industries we serve who use bearings in their applications, we found it much easier to make a list of who doesn’t use bearings! If you extract, process, convey, or manufacture just about anything, you need bearings! Click here to view our line of bearings.